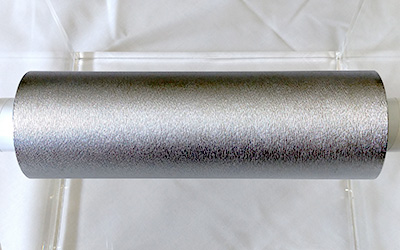

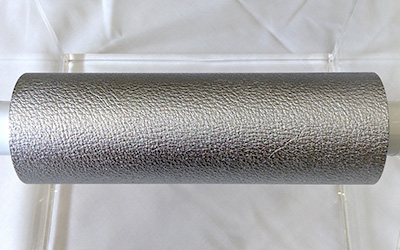

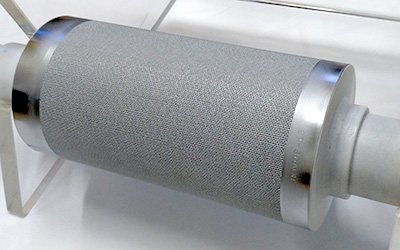

EMBOSSED ROLL

EMBOSSED ROLL ENGRAVING

Used for : Laser Processing, Embossing roll for Vehicle Interior Materials, Relief embossing roll, Texture embossing roll, The process of Engraving for Roll, Engraving on Hard Material Roll.

In this etching process three-dimensional designs or textures are milled onto the roll’s surface (Etching Press), this product is used for embossing wallpaper, floor and ceiling tiles, leather, vinyl and paper. Each three-dimensional pattern is engraved on a steel core roller, which has a diameter ranging from 20 mm to 600mm.

ETCHING EMBOSS ( MULTISTAGE ETCHING )

ANILOX ROLL

ANILOX ROLL ( Surface Process for Hexagon, Pyramid and so on. )

Used for : Coating, Laminating, Bonding (Adhesives), Glue roll Glue, Roll for Processing of Adhesive Tape, Bonding Roll,, Diagonal lines ( Trihelicoid), Millor Processing Roll, etc.

For both coating and bonding, a variety of mill types are available. Roller mill techniques such as our guadra-gravure, pyramid, hexagonal, or transformed quadra-gravure types may be used. Our rollers are produced in diameters ranging from 20mm up to 500mm, and of lengths up to 4,000mm. A variety of cell shapes may be engraved on steel core rollers or copper plated rollers. The durability of the rollers is insured by the final process of nickel or chrome-nickel plating. Then the rollers are ready for their use in printing, bonding or embossing. Currently, the company is also developing and manufacturing precision rollers.

All kinds

- Quadra Gravure

- The engraved roll has a gravure type trapezoid cell. and the foam has been cut the top of pyramid. compared with same mesh, it foams cell deeper than pyramid type’s and 20 to 50% of ink quantity can be transfered. It is possible to use a doctor blade.

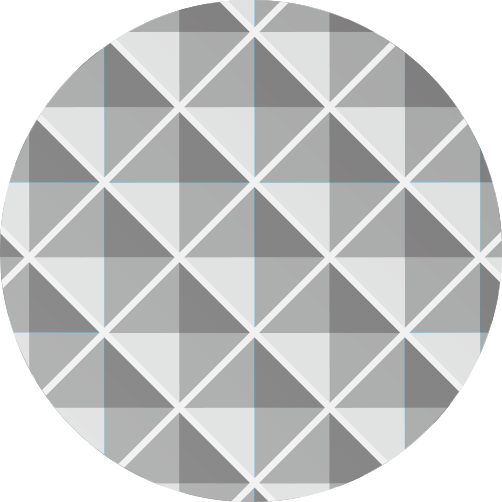

- Pyramid

- Because it is an engraved square spindle, it is called the pyramid. Mainly, it is suited for a low supply of ink. The bank width is narrower in comparison to other cells and has a tendency to increase wear. So, it is not suited to the use of a doctor blade.

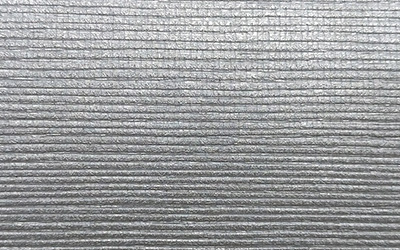

- TriHelicoid

- This V style ditch is engraved on the spiral and is suitable for liquids of a thicker nature with high viscosity like glue, wax and magnetic paint. It is possible to use a doctor blade.

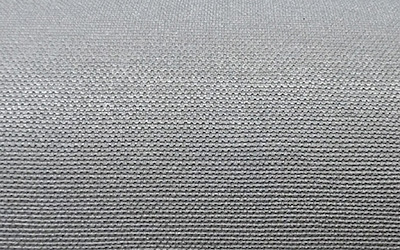

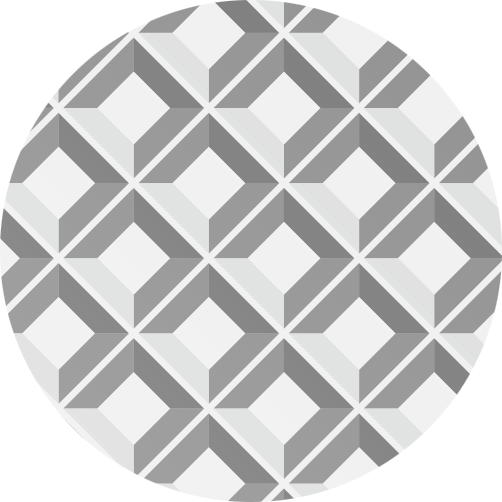

- Hexagonal

- This cell structure is hexogonal, like the carapace of a tortoise. Compared with tetrahedron cells like pyramid and quadra gravure, the durability when using a doctor blade rises. The heavier nature of the ink is good, and it is optimal for both halftone printing and line printing. This cell structure also prevents moir.

- Transform

- As for cell structure, making bank width on both right and left of Quadra Gravure into rectangle and it is formed the angle of 45 degrees to 60 degrees against total-length. Especially, it is possible for even printing that is able to prevent vertical lines by liquid flow at that time of high speed operation.

Characteristics

The anilox roll is fundamentally machine engraved. The angle of the cell-wall on the engraved roll is sharp and equalized. This wider bank width results in higher durability. So, cell capacity is obtained precisely with transfered quantity. Engraving is that, embossing is performed by a special prototype-mill which pressure engraves the roll, continuing to form the cell until completion. After that, a hard-chrome process is done to 10~20 μ of thickness.

Function

- 1. Making 凹 of the cell on metal cylinder endlessly, you can control ink transferred amount with the cell capacity of the part.

- 2. No vary with high accuracy, even thickness is available in ink-transfers.

- 3. Even the ink use of high clay is possible.

- 4. Acting doctor blade, the transfers of even and thin ink membrane is possible. It has an effect in the process printing.

- 5. Same as gravure cylinder, being processed by copper, nickel and chrome-Plating by machinery method, durability and pair corrosion performance improve substantially.

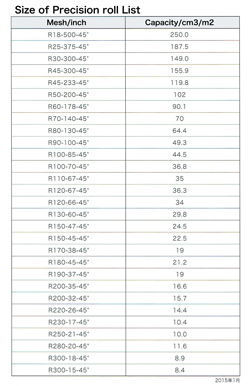

Please click each following list, and you can see details clearly by PDF.

Attention for Anilox Roll’s operation

An Anilox roll’s life is not permanet. The length of usefullness depends upon the frequency, and method of roll use. The rough-standard, using a 2 roll-method, is a few years or using a steel-doctor blade for 50~1,500,000 meters. There are two methods commonly used to re-engrave rolls. The first is to re-engrave after polishing and the other is to re-engrave after modifying with a copper plating process.

The Anilox roll is already hard-chrome plated. Due to the solutions being utilized, corrosion sometimes occurs with cracking and damage to the chromium layer. But, there is a method to strengthen the roll with a barrier layer of nickel plating.

Please feel free to ask us about other mesh/inch and capacities you hope to use. Also, do not hesitate to ask us about any problems with closed-holes you may have.

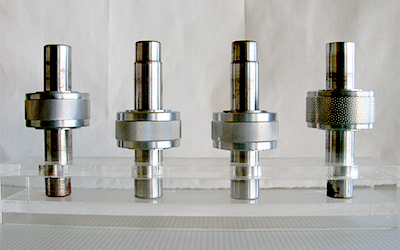

PRECISION ROLL

Used for : Coating for thin-membranes, Roll for Coating, Coater Roll, Precision Roll, Coating Roll, Thin Coating Roll for film, for Battery processing, for Environment Energy Reserch and Development, for Transparent Conductivity Film processing, for AR Film Processing, for AG Film Processing, for Adhesive Tape Processing, Diagonal lines ( Trihelicoid).

It is possible to process rolls ranging from 20mm to 80mm of diameter. ( Click below for a PDF list )

GRAVURE ROLL

DIRECT GRAVURE ENGRAVING

Engraved rollers for gravure printing ( etching method )

Used for : various wallpaper, flooring, leather, corrugated cartons.

TEST ENGRAVED PATTERN BY GRAVURE ENGRAVING

Used for : proofs of gravure printing ( etching & electro-engraving method )

PRECISION DIRECT ETCHING ENGRAVING

Engraved rollers for precision printing ( etching method )

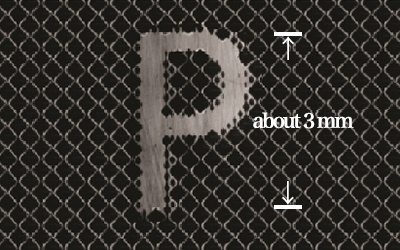

Used for : precision printing. film reflecting print such as transferred emboss, that is possible to process 3μof engraving depth, Bonding Roll, Metal Etching Process, Deep Depth Etching Process (Corrosion), Shallow Depth Etching Process (Corrosion), Microfabrication, High-Definition Process, Engraved plate Engraved Plate Processing, Harftone Dot, for Battery Processing, for Environment Energy Reserch and Development, Moire-less Processing.

ELECTRO ENGRAVING PROCESS

Engraved rollers for gravure printing ( electro-engraving method )

Used for : various wallpaper, flooring, leather, packaging, corrugated cartons Possible to process from 70 to 400L/inch of Roll.

HYBRID ENGRAVING

Hybrid Engraving ( Hybrid System ) is that a Conventional cell-form realized by diamond-engraving and it is available for the best ink performance transferred by halftone in all gradations.

COPPER PLATED IRON ENGRAVING

Engraved roll for textile printing.

Used for : clothing, bedding

For more information about any of our products, please feel free to contact us.

PHONE.81-73-423-5205 FAX.81-73-428-0227